St. Jude Family of Websites

Explore our cutting edge research, world-class patient care, career opportunities and more.

St. Jude Children's Research Hospital Home

- Fundraising

St. Jude Family of Websites

Explore our cutting edge research, world-class patient care, career opportunities and more.

St. Jude Children's Research Hospital Home

- Fundraising

Shared Resource Spotlight: St. Jude Vector Laboratory (SJVL)

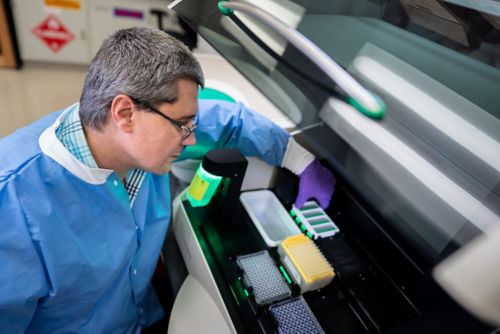

Scientist Francesca Ferrara, PhD, at work in the St. Jude Vector Laboratory.

For a letter to reach its intended destination, it must be properly addressed, posted and transported by a mail carrier. For genes to be transferred or introduced into a new system or organism, viral vectors must play the role of molecular couriers, facilitating the change of targeted cell types or tissues with unparalleled precision. The St. Jude Vector Laboratory (SJVL) shared resource, led by Robert Throm, PhD, creates and deploys these essential viral vectors for genetic research and therapeutic development.

Gene therapy — the modification of select genes or portions of the genome to correct and treat dysfunction or disease — depends on safely delivering genetic information to targeted cells. Viral vectors are how scientists accomplish this; they are biological tools that leverage the natural ability of viruses to transport their genomes into the cells they infect.

The mission of the SJVL is “advancing innovative viral vector technology and research for the treatment of catastrophic pediatric diseases.” This statement captures the team’s dedication to a cause extending beyond conventional research.

Brandon Lowe, PhD, manager of lab operations at work in the St. Jude Vector Laboratory tissue culture hood.

Creating viral vectors

The SJVL shared resource uses three main types of viral vectors: lentiviral (LV), gamma retroviral (gRV) and adeno-associated viral (AAV) vectors. “This year, I estimate we’ll make about a thousand vector preparations for St. Jude researchers, and about 80-90% of those will be lentiviral-based,” explains Throm.

Lentiviral vectors are employed in studies involving dividing and nondividing host cells and have several other advantages in cell and gene therapy applications. They can effectively introduce a large amount of genetic material into specific cells with a low immune response and infect cells regardless of whether they are actively dividing. This flexibility enables the transduction and genetic modification of nonreplicating cells.

Throm and his team also aid in vector design, producing preclinical research-grade vectors, troubleshooting issues and facilitating the transition to clinical-grade materials for St. Jude Investigators. Francesca Ferrara, PhD, a scientist in the SJVL, highlights her role, “I focus on developing new tools to advance our day-to-day operations and help other St. Jude Investigators.”

Engaging with over 18 departments and 53 principal investigators across St. Jude in 2023 alone, the SJVL team is in constant motion. “We’ve reached a pretty broad audience; we’re just getting busier as the institution expands,” Throm says. The team continually increases their output, preparing an expected 1,000 vectors in 2024, up from 744 in 2023 and 500 in both 2022 and 2021.

Innovative Approach to Vector Development

Led by Ferrara, the SJVL team developed virus-like particles (VLP), an effort that included making the plasmids, validating them, producing the VLP and testing them on primary T cells. Throm notes, “They are very effective, with a greater than 80% editing efficiency, depending on the target.”

Like standard LV, VLPs are a seamless technology transfer to Good Manufacturing Practice (GMP), a shared resource at St. Jude. This process leverages the institution’s resource expertise.

Throm emphasizes, “They do not interfere with the process of CAR-vector delivery whether by LV or gRV.” He adds that compared to electroporation with Ribonucleoprotein (RNP), VLPs need “less cell handling, are milder, meaning fewer patient cells are needed — a very important aspect — and are significantly cheaper.”

The estimated savings are an impressive $700,000 per project (30-50 patients). This VLP technology enhances gene therapy affordability and efficiency, showcasing the SJVL’s leadership in innovative viral vector technology.

Senior scientist Matthew Wielgosz, PhD, at work in the St. Jude Vector Laboratory.

Vector Support in Clinical Applications

In a publication in Molecular Therapy Methods & Clinical Development led by Matthew Bauler, the SJVL team demonstrates the potential for the large-scale clinical-grade production of lentiviral vectors. They develop novel cell lines and optimized production methods that address key challenges associated with traditional production systems to advance the manufacturing of lentiviral-based cell and gene therapies.

The team also looks at the clinical applications of their system, demonstrating the crucial role it plays in T-cell immunotherapies.

Throm explains, “We help bone marrow transplantation and cellular therapies with many of their T-cell immunotherapies.” This involves guiding investigators in vector design, producing preclinical research-grade vectors, and facilitating the transition to clinical-grade materials.

“We’ll make preclinical research-grade vectors and find out which ones work best,” says Throm. “If investigators have any problems, we try to troubleshoot.”

This commitment to contributing to scientific knowledge advances the SJVL team beyond a service provider, positioning them as dynamic contributors to the evolving field of vector technology.

Throm collaborates with researchers both within and outside the institution. “The St. Jude Vector Laboratory regularly provides high-quality, research-grade vectors in a timely fashion to our group for developing manufacturing processes for cell and gene therapy products, including CAR T cells,” states Albert Zhou, PhD, St. Jude Experimental Cellular Therapeutics Laboratory director.

This synergetic collaboration demonstrates how shared expertise and resources within the institution contribute to the overall success of St. Jude investigators in advancing cutting-edge therapies. Regular communication channels, such as presentations at meetings, conferences and publications, ensure a dynamic exchange of ideas and advancements between shared resources, empowering the SJVL team to stay abreast of cutting-edge vector technology.

Unique advantages of working with Vector Development

A significant advantage of utilizing the SJVL’s services is its cost-effectiveness. Throm emphasizes this point by comparing the costs of his team’s services to alternative means. “To get a vector of equal quality and volume outside the institution, people would probably have to spend potentially $50,000, whereas we can provide it to them for $300.” The resource’s ability to provide high-quality vectors at a fraction of the cost underscores its commitment to supporting research endeavors within St. Jude.

Navigating challenges are inherent in vector production. “Garbage in and garbage out,” says Throm, stressing the importance of working with good-quality material from the start. “I want people to have trust in the quality of the product they’re getting back,” he states.

Ferrara adds, “Recently, we developed an in-house long-read plasmid DNA sequencing method that we use routinely for screening and checking that the material provided by St. Jude Investigators for vector production is as expected.”

The team’s meticulous quality control measures underscore their commitment to delivering high-quality material to researchers.

“The SJVL also continues optimizing vector production methods to facilitate GMP vector production. These efforts are in addition to all the other services they provide to St. Jude investigators,” says Zhou.

Together, the team ensures that, through meticulous quality control and ongoing optimization efforts, high-quality vectors that meet and exceed researchers’ specifications for clinical applications are delivered.

The Human Element

The SJVL team’s relentless work pace is instrumental to the quality of the material that St. Jude investigators receive.

Throm highlights the team’s efforts in maintaining morale, sharing insights into their cross-training approach and ensuring a dynamic and engaged team. “It’s a total team effort. We try to change it up so everybody’s engaged."

This group dynamic is essential as the SJVL plans to expand equipment to meet the increasing demand, showcasing the core’s adaptability. “Every year, we’re just getting busier and busier as the institution expands.”